A Lid-hinged Box, also known as clamshell box is a protective box with a hinged lid attached to the base. Both the lid and bottom sections of the hinged box have three fixed side sections.

The exterior is laminated with leather and filled with foam. The interior is wrapped with velvet fabric.

Crafted from high-quality materials, these boxes feature a hardcover, book-like structure that not only adds an air of sophistication to your product but also provides enhanced durability and stability.

Order(MOQ) :

3000Payment :

30% deposit,70% against copy of bill of ladingProduct Origin :

ChinaPrinting :

4-color(CMYK), Spot-color(Solid Color)Material :

157~220gsm art paper+ 800~1800gsm Grey boardCoating :

Gloss, Matte, Soft touch, Embossing, Debossing, Spot UV, Golden/Silver Hot Stamping, holographic foil.Shipping :

Ship to any port or Door to DoorOptions :

Window Cut Out, Plastic Vacuum Tray or Foam inserts, Silk & velvet lining, Card Paper Partitions, Magnetic & ribbon closure, Greeting Card, Wrap Papers.

Our book style rigid boxes are versatile and durable packaging boxes that feature a unique book-like design. The boxes are made from high-quality materials such as paperboard, graybeard, and fully recyclable Kraft paper that provide extra protection to your products. We use the latest printing technologies including offset digital printing, CMYK, PMS, UV printing, and foil stamping to ensure your design is beautifully replicated on the box.

Our rigid boxes are suitable for a wide range of products, examples include:

Food and beverages (chocolates, sweets, bakery, coffee, tea etc.)

Cosmetics (perfume, lotion, serum, makeup, etc.)

Luxury goods (Jewelry and watches and accessories, etc.)

Fashion apparel (clothing, bags, shoes, tie, sunglasses, etc.)

Electronics (smartphones, tablets, headphones, etc.)

Stationery (notebook, brochures, pens, tools etc.)

Craftworks (souvenir, tableware, gifts, etc)

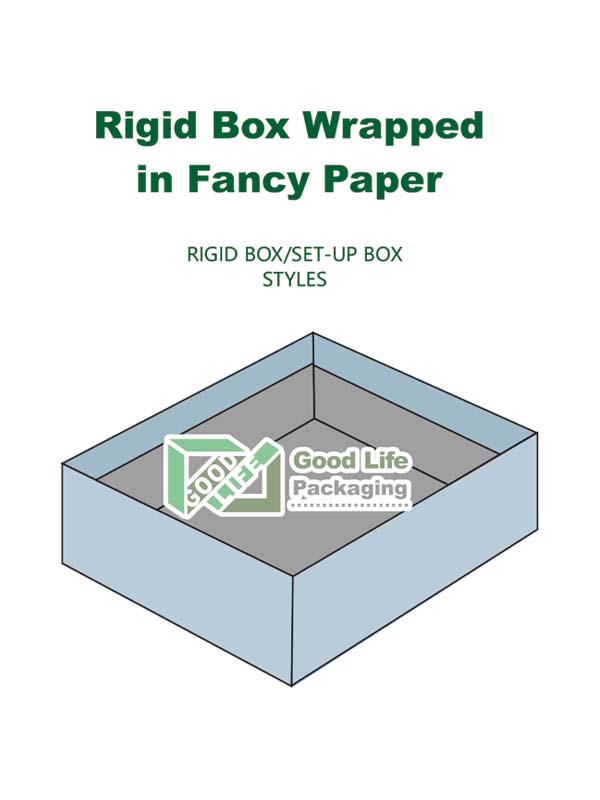

Rigid boxes are typically four times thicker than regular folding cartons and are usually not printed directly on them. Instead, they are wrapped in paper and can be as simple or as luxurious as you like.

Their processes are either completed by machines, manual labor, or various combinations of the two, depending on the specific requirements.

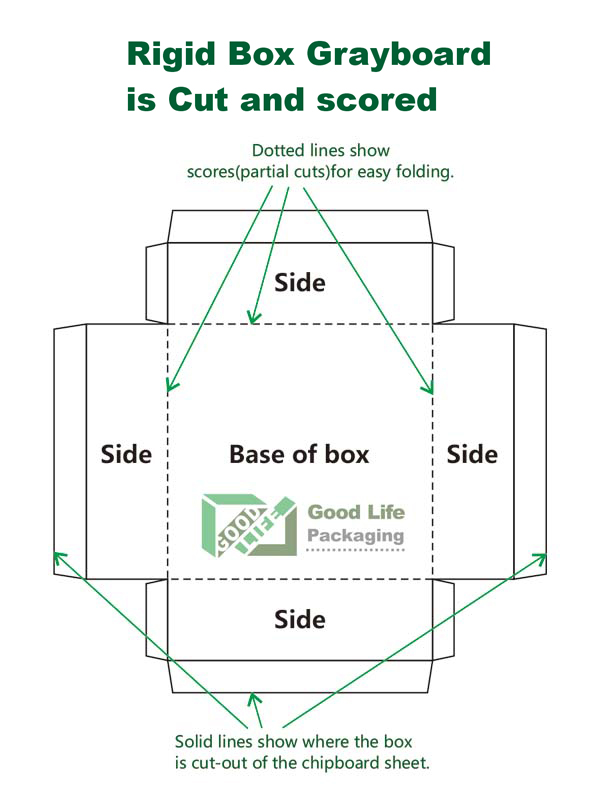

The rigid box is sturdy because of using hard gray board or plain board, also be chosen to provide color for the inside of the box). Cutting and engraving molds are used to cut boards into the correct shape and size, while also engraving the sides of the box.

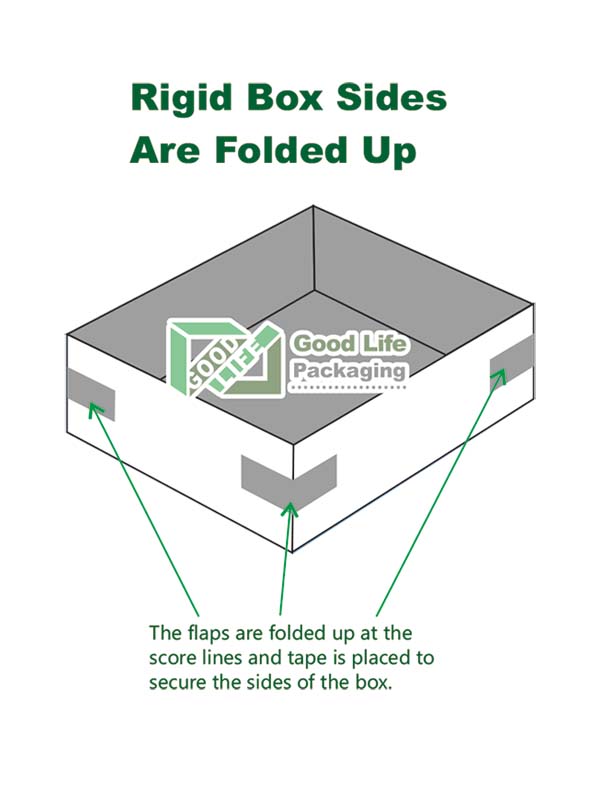

The sides of the box fold up in the scored area to create the shape of the box. The sides are then taped, or "pinned," using a machine called a four-bracing machine.

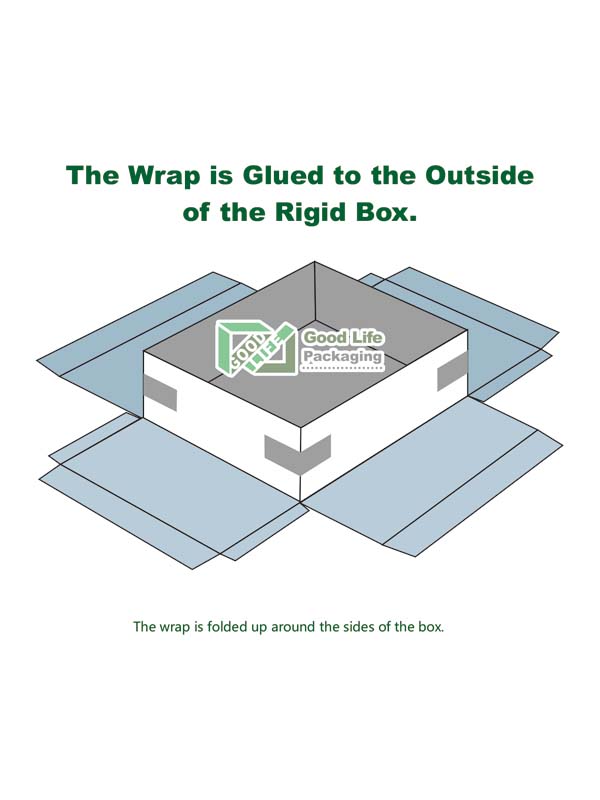

The wrap is prepared by printing (if required) and then trimming or "mitering" to fit the box exactly. Then place the box over the packaging and glue the two together.

Wraps can be in all types of paper or fabric, with stunning textures, colors and finishes (i.e. high gloss or matte), including embossing, debossing, foil stamping, spot UV and hologram.

For a look at different kinds of custom box embellishments click here.

Wraps can also be wrapped tightly or loosely around the box. Traditionally, when rigid boxes were handmade, packaging was always loosely wrapped. The standard now is to wrap the box tightly. One can often still opt for loosely packed rigid boxes; it gives the box a handmade feel and is therefore more expensive and luxurious.

Call Us

Call Us Email

Email Address

Address